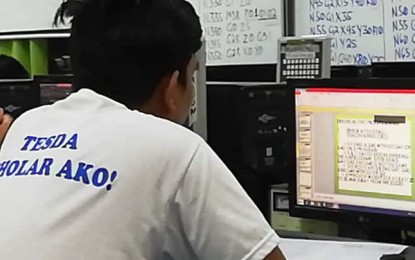

A Computerized Numerical Controlled (CNC) machining skills trainee of the Technical Education and Skills Development Authority- Cordillera Administrative Region (TESDA-CAR) training center in Baguio City. TESDA-CAR recently linked with international aerospace company Moog Controls Corporation for the training of industry- specific machinists. (PNA photo by Liza T. Agoot)

BAGUIO CITY-- The partnership between the Technical Education and Skills Development Authority in the Cordillera Administrative Region (TESDA-CAR) and MOOG Controls Corporation, a foreign aerospace company in the city, is proving to be an effective collaboration between the government and the private sector.

“The program is aerospace industrial manufacturing technology partnership with MOOG Controls. This is an old partnership but is is now called the Enhanced Core manufacturing partnership to suit the needs of the industry’s changing technology,” TESDA-CAR Acting Regional Director Manuel Wong told the Philippine News Agency (PNA).

Moog Controls Corporation is an international company producing spare parts for airplane like actuators and servo valves.

Through the partnership, a Certificate of Training Program Registration (CTPR) was issued by TESDA to certify the training provided by the company as within the core competency and regulation of the agency.

Wong said under the program, the trainees are provided with the basic machining training at the regional Training Center in Loakan.

The advanced training will be done at the Moog Controls facility inside the Baguio City Export Processing Zone Area (BCEPZA), where the trainees will be trained using the actual equipment and technology used by the company in producing the airplane spare parts, Wong said.

He said under the current partnership, there will be 15 to 20 trainees to be chosen after a stringent screening.

“Medyo stringent ang screening kasi malaki ang chance of absorption after the training (The screening will be stringent considering that there is a big chance of being hired after the training),” Wong said.

Hector Laguardia, TESDA Regional Training Center administrator, said the partnership has led to the training for machining, producing specialized items made specifically to suit the product of Moog Controls and the aerospace industry.

TESDA Training Institution

The government has invested over PHP100 million in terms of equipment for the machining skills training of TESDA-CAR.

Laguardia said in the Philippines, there are only three training institutions providing such skills-- one in Davao, the other in Cebu and the one in Baguio at the regional office.

He said aerospace machining became a critical skill after several employees of Moog Controls were pirated by other foreign companies, prompting TESDA to partner with the firm in the 90s to assure the availability of manpower resources locally.

For several years now, TESDA-referred machining graduates applying with the company are given preference at being hired.

Laguardia said the training Certificate of Training Program Registration issued to Moog is a No Training Regulation (NTR), meaning the curriculum that will be used in the training will be specific to Moog Controls.

The training with TESDA will be in two stages that will last for more than five months, with 1,340 hours or 160 days devoted to the acquisition of the basic and common competency.

The trainees’ conventional training will last for 2 and a half months. During this time, everything will be manually done using the equipment that the government has invested at the regional training center.

The trainees will learn the bench work, grind work, lathe and the milling processes in machining skill.

For the three months, the trainees will also undergo the computerized numerical controlled (CNC) machining system where the computation of the weight, size and all factors that affect the precision of the spare parts will be computed.

After completion of the five-month training, they will have to acquire a National Certification from TESDA to assess their readiness and qualification.

It will be followed by the core competency training that will be conducted by Moog inside their facility.

Laguardia said during the training, Moog pays for the training allowance which will be compliant with the training allowance under the Labor Code of the Philippines.

TESDA trained workers

Laguardia said over 500 machining trainees, who have all acquired a National Certification, have been produced by the TESDA.

He said it is not only at Moog because TESDA graduates have a big chance of being employed, locally or overseas, as machining experts.

“Our graduates are highly in demand,” he said.

To date, there are 25 machining trainees at the regional training center, some of whom are on scholarship grants.

Laguardia said most of the paying trainees are employees of companies and were required by their employers to acquire the skill or to enhance their machining skills.

Noriel Ramos, trainer and assessor for CNC machining, said machining is a skill where the trainee will learn to produce goods or products made of metal using a machine.

The machining program is covered by a National Certification (NC) 11. (PNA)